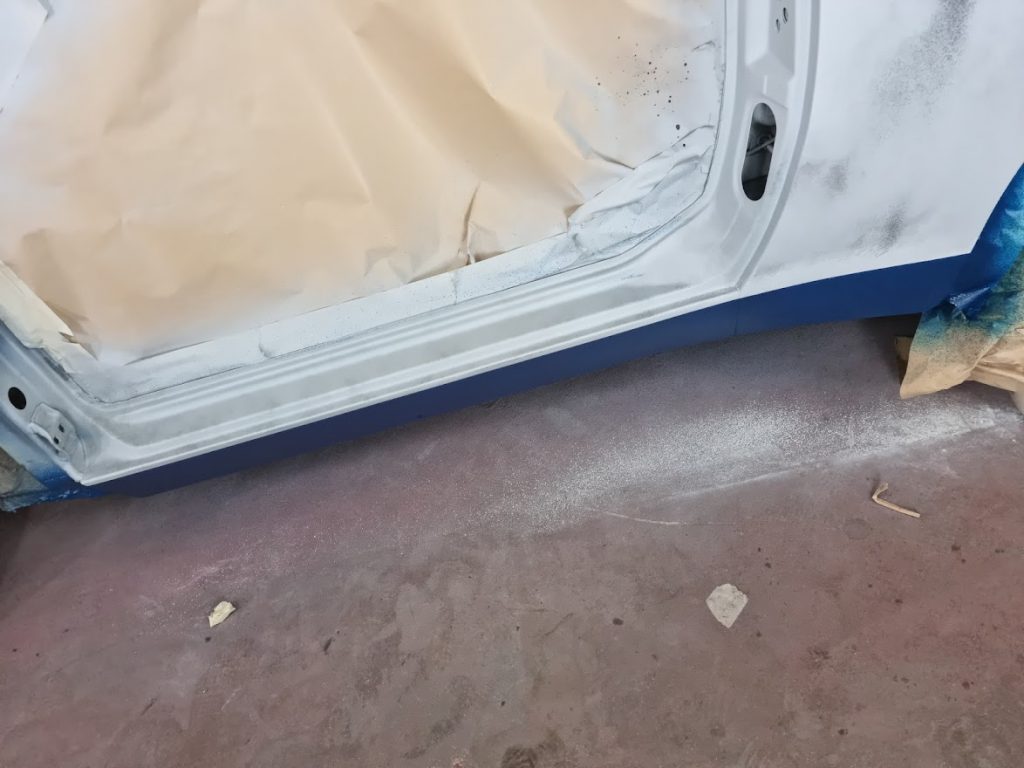

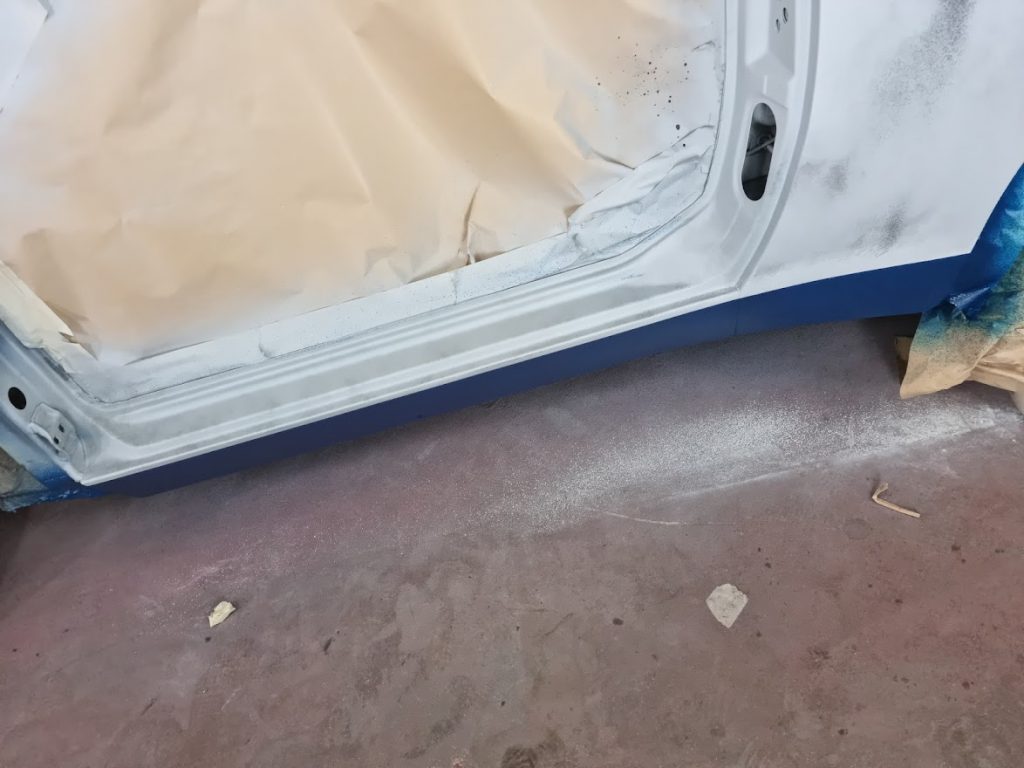

We were comissioned to carry out extensive welding repairs to this lovely blue Porsche 944 S2. In this post we will show some of the steps in the process from start to finish.

We were comissioned to carry out extensive welding repairs to this lovely blue Porsche 944 S2. In this post we will show some of the steps in the process from start to finish.

© 2024 Augment Automotive Limited - Companies House Registration 07593525 - Terms and conditions